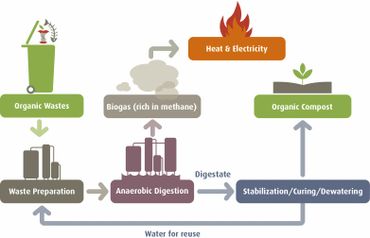

Anaerobic digestion is a series of biological processes in which microorganisms break down biodegradable material in the absence of oxygen. One of the end products is biogas, which is combusted to generate electricity and heat, or can be processed into renewable natural gas and transportation fuels.

Anaerobic digestion is widely used as a source of renewable energy. The process produces a biogas, consisting of methane, carbon dioxideand traces of other ‘contaminant’ gases This biogas can be used directly as fuel, in combined heat and power gas engines or upgraded to natural gas-quality biomethane. The nutrient-rich digestate also produced can be used as fertilizer. With the re-use of waste as a resource and new technological approaches which have lowered capital costs, anaerobic digestion has in recent years received increased attention among governments in a number of countries.

Flexibuster® (EXAMPLE OF ONE TECHNOLOGY)

FLEXIBUSTER® (EXAMPLE OF ONE TECHNOLOGY)

FLEXIBUSTER® (EXAMPLE OF ONE TECHNOLOGY)

The Flexibuster™ has been designed and engineered to turn a wide range of organic waste into energy.

Flexibuster™: Can be delivered to site ready for plug-and-play installation, and which turns your organic waste into energy right at the point where the waste is generated and the energy is required.

Flexibuster™ has been designed to provide a logical and sustainable way of capturing the energy that remains in food waste. Instead of paying for this waste to be taken away and processed somewhere else, why not turn that waste into free energy and heat on-site? The containerized anaerobic digesters (AD) are fully automated and remotely monitored. You tip your food waste into the mouth at one end and simply leave the rest to Flexibuster™. State-of-the-art sensors and controls will automatically prepare this material for digestion and control the flow of the material through the system.

FLEXIBUSTER® (EXAMPLE OF ONE TECHNOLOGY)

FLEXIBUSTER® (EXAMPLE OF ONE TECHNOLOGY)

FLEXIBUSTER® (EXAMPLE OF ONE TECHNOLOGY)

The patented process extracts maximum energy from the waste stream in the form of Biogas which is then used to fuel a CHP engine to provide electricity and heat. Because of the built-in pasteurisation process, Flexibuster™ can process a wide range of feed-stocks in a completely safe, odor free environment.

- Turns food waste into energy

- Small scale: Handles between 1,100 lb and 6,600 lb (500 kg and 3,000 kg) per day

- Cost – effective renewable energy generation and waste management

- Short pay-back period

- Modular design

- Rapid install

- Remote monitoring

- Low maintenance, rugged and reliable design

LOCAL

CARBON OFFSETTING

CONTAINERIZED

The FLEXIBUSTER™ allows you to process your waste into carbon-free electricity and heat locally, on-site, eliminating the necessity to transport waste to centralized processing plants.

CONTAINERIZED

CARBON OFFSETTING

CONTAINERIZED

The systems are fully contained in standard shipping containers, allowing easy transport and install, at low cost, without difficult permitting issues and with effective odour control.

CARBON OFFSETTING

CARBON OFFSETTING

CARBON OFFSETTING

The FLEXIBUSTER™ offsets 385 tonnes of CO2e for every 1,000 metric tonnes of processed food waste, aiding large corporations to meet their sustainability metrics and salable on the carbon markets

MUCKBUSTER® (EXAMPLE OF ONE TECHNOLOGY)

MUCKBUSTER® (EXAMPLE OF ONE TECHNOLOGY)

MUCKBUSTER® (EXAMPLE OF ONE TECHNOLOGY)

Muckbuster® is the right solution for turning slurry and similar farm waste into energy in the form of electricity and heat, whilst generating high value fertiliser as a by-product.

The Problem: Manure, slurry and similar waste streams are creating a waste management headache on a global scale. Increasing levels of legislation and taxation are making it harder to spread this waste material on agricultural land. Removal from site to a centralised treatment facility is often not financially viable.

The Solution: Muckbuster® has been designed specifically to treat slurry, manure and similar waste streams in an award-winning, containerised Anaerobic Digestion (AD) unit that captures the energy potential of organic waste.

Muckbuster® is delivered to site in a series of standard shipping container units and can start to generate energy from waste within 2 weeks of delivery to site. Once installed, slurry is pumped into the unit where it is digested by bacteria that release Biogas as part of the process. This biogas is then used to fuel a CHP engine which provides Electricity and heat to the site.

MUCKBUSTER® (EXAMPLE OF ONE TECHNOLOGY)

MUCKBUSTER® (EXAMPLE OF ONE TECHNOLOGY)

MUCKBUSTER® (EXAMPLE OF ONE TECHNOLOGY)

Non liquid waste streams can be fed into an optional mouth unit for pre-processing before they enter the main AD unit.

Our technology is designed to be rugged, reliable and requires minimal intervention. The fully automated system is remotely monitored to ensure a safe and efficient operation at all times.

- Turns poop into power

- Flexible and scalable technology suitable for small and medium size sites

- Low cost solution for turning waste to energy

- Short payback period

- Rugged, reliable, proven technology

- Fully automated

- Remote monitoring